A Brief Review of Seaweed Harvest Value Chains- Juniper Publishers

Juniper Publishers- Journal of Oceanography

Abstract

Key to realizing the vision of marine agronomy and seaweed utilization is an understanding about all steps necessary to collect and prepare the seaweed for processing (i.e., feedstock harvest, preprocessing, and logistics), as well as the costs and benefits of commercial implementation. Toward that end, the objective of this study was to examine the peer-reviewed scientific literature and other commercial information sources to identify and quantify key cost data. Specifically, this project focused on seaweed harvesting, drying, densifying, and transporting. This project did not, however, examine either growth/cultivation or the subsequent processing of the dried seaweed. Those topics, while important, will be the subject of a separate paper.

Introduction

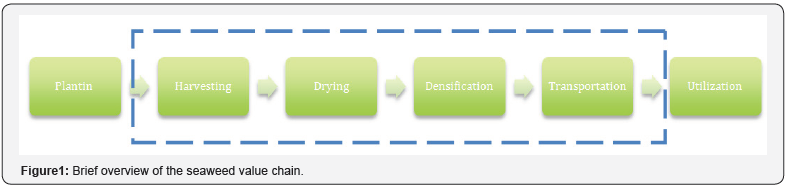

In recent years, mariculture has become a fast growing food sectors, not just in China and the Far East, but around the world, with an annual growth rate of 4-11%. This rapid growth is likely due in part to the large area of “usable space” in the ocean and along coastlines, as well as the quantity of biomass (i.e., type of seaweed) that can be produced and harvested [1,2]. In addition, many types of seaweeds can be sources of proteins, and they have unique compounds that can be used for animal feeds, bio-based fuels, pharmaceuticals, and other products. A unique advantage of this type of systems is that growing seaweed consumes excess nutrients and CO2, which are two compounds believed to have ecologically dangerous impacts [1]. With these benefits to the marine agronomy, it is not hard to see why scientists and engineers are interested in developing this unique industry. While on paper, harvesting seaweed seems like a simple task, there are a number of important steps in the process, which have been identified in Figure 1.

For the purposes of this paper, we will only discuss the harvesting, drying, densification, and transportation portions of the value chain. A basic review of these components of the supply chain will be useful as various companies consider the opportunities, benefits, and potential challenges in the supply chain, which might be present for implementing marine agronomy.

Harvest

There are a variety of ways that offshore seaweed can be grown and harvested. Typically seaweed “farms” will grow seaweed attached to either lines or ropes, in order to provide a consistent structure for the farm. The most widely practiced harvesting method for seaweed is manually by hand. This practice often occurs in China, Indonesia, and the Philippines [3]. Small boats with teams of only a few people go out with various hand-held equipment (such a knives), then they cut and pull the seaweed into a net. The cargo is then brought to shore for drying and processing. In a study by Kelly [4], they found that a team of three to four people can harvest and land approximately 4 t/h. Hand harvesting may produce the lower quantity of ecological impact, but is not as efficient as mechanized systems, which are becoming more popular in recent years [5].

Scoubidou

There are multiple types of mechanical harvesting, depending on the type of seaweed that is grown, where it is grown, and how it needs to be harvested. A common machine allows young seaweed to continue to grow, but it harvests the mature portion of the plant using a sickle-style hook, which is known as a “scoubidou”. This is attached to a crane-mounted pole, and the boats are typically 8 to 12 meters in length. The boats are generally outfitted with one to two scoubidou apparati, and have a cargo capacity of 10-20t of wet seaweed. To harvest the seaweed, the scoubidou is lowered into the seaweed, it is moved sideways, which causes the seaweed to become tangled in the hook. Only plants larger than about 60cm stay hooked, leaving the smaller plants (which are often younger than two years of age). This device is often used to harvest Laminaria digitata in France, and can pull around 1.5-2t of wet weight per day, with each harvest of ~10kg taking ~30sec [6]. Perez [7] found no clear advantages to seaweed harvest time when harvested using the scoubidou method vs. other methods. The scoubidou method can also be used formanual hand harvesting, as the operator controls the sickle blade by hand.

Dredge

Another method for seaweed harvesting is to use a dredge, which is to pulled across the ocean floor. This method is limited to areas, which do not have rocks or boulders. Modern dredges are attached to a boat with a carrying capacity of 30-1850t, depending on the owner, by using a crane. The dredge can harvestapproximately 2t per harvesting pass, which typically lasts from 0.5 to 2min, at a range of depths - often from 2 to 20m. In theory the dredge cuts the seaweed 5-20cm from the holdfast, but they are known to pull the entire plant up instead. By using a dredging technique, the top layer of seaweed is removed, which allows that at the bottom to then receive sunlight, and thus grow [6].

Vertical Wet-Well

Vertical wet-wells were described by Kelly [4], where depth gauges were attached to hydraulic arms that maintained the wet-well near the bottom of the sea floor, and the seaweed plants were attached to this system. This machine chopped the seaweed and conveyed it up to the boat. The depth gauges were used to prevent the machine from cutting too close to the base of each seaweed plant,and they maintained a distance of about 20cm from the sea floor. This type of system was tested at two shorelines, they found very different results: at one shore they were able to harvest at a rate of 0.2 t/h (it was difficult to bring the large boats and their harvesting machines close to shore, to maneuver, and to cut the seaweed), at the other shore the harvest rate was 1.125 t/h, as maneuvering and cutting was much easier [4].

Mowing Boat

Finally, there are mechanical harvesters that are premanufactured. For example, Conver (www.conver.com), which is a company from the Netherlands, manufactures equipment for seaweed harvesting. Their Conver C430H system is a mid-size mowing boat, which hasa T-shaped cutting tool at the front of the boat for cutting seaweed, and after cutting the boat pushes the seaweed to a collection net. This boat has a width of 1.5m, which is fairly small compared to the aforementioned options; it can maneuver well and allow the operator to get close to shore, which can lead to increased seaweed harvesting efficiency [8].

Drying

Research has been performed at the Universiti Kebangsaan Malaysia using solar drying methods for seaweed. One study focused on conducting a cost analysis of various types of solar drying systems; they noted that drying options which meet technical and socio-economical requirements, but which are cost-effective, are available [9]. Using a solar-powered, forced-air convention dryer, the seaweed started with an initial moisture content of nearly 90% and was dried to a moisture content of approximately 10%, which took approximately 15 h (solar incident radiation of approximately 500 W/m2 and air flow of 0.05 kg/s) [9]. Fudholi found more energy can be absorbed by the collector solar array of the dryer if the intensity of the solar radiation increases [9]. In another study performed at the Universiti Kebangsaan Malaysia using the forced convection drying system, seaweed was dried from 94.6% moisture content (wet basis) to 10% moisture content (dry basis) using a solar incident radiation of 600W/m2 and an air flow rate of 0.0613kg/s, took approximately 7h [10]. The initial mass of the seaweed was 120g, and the final mass of the seaweed after drying was 11g, which resulted in 109g of water loss [10]. Fudholi was able to predict the moisture ratio using the Page equation: MR = exp(-1.6054t0.566); this model was 96.7% accurate [10].

The Universiti Kebangsaan Malaysia also performed research using a Low Temperature and Humidity Chamber Test to determine the optimum temperature and relative humidity for drying seaweed [11]. Fudholi compared three temperatures (40, 50, and 60 °C) to three relative humidity levels (10, 25, and 40%) using a constant air velocity of 1m/s, while recording the weight every 5min [11]. In conclusion, drying at 60 °C at a relative humidity of 10% produces the best quality of seaweed, using the Page model equation (MR = exp(-2.23474t1.1247)), which was 99.3% accurate [11]. Using the same experimental protocol, the drying curve mathematical model was determined for brown seaweed (Eucheuma cottonii), which is also the Page’s model [12]. In conclusion, both the temperature and the relative humidity of the drying air affect the drying time of seaweed [10].

Chan (Chinese University of Hong Kong) performed a study comparing how the type of drying affects the nutrient composition of Sargassum hemiphyllum [13]. Sun-drying, oven-drying, and freeze-drying were compared, and seaweed was analyzed for moisture content, crude protein, amino acid composition, fatty acid composition, dietary fiber, ash, mineral elements, and vitamin C. Chan found that the freeze-dried seaweed retained the nutritional composition best because it contained the highest contents of vitamin C, amino acids, and polyunsaturated fatty acids.

Henan Quiangyuan Machinery Co., Ltd is a manufacturer of machinery located in China [14]. The company produces a high quality seaweed vacuum dryer starting at $10,000; the counter-flow dryer is efficient, easy to operate and maintain, and aesthetically pleasing. Another vacuum dryer is produced by WD, which is based out of Jiangsu, China. The WD dryer starts at $2,000, and saves energy, produces sanitary and low noise working conditions, and produces easy and uniform temperature controls. Changj in, a manufacturing company based in China, produces a conveyor dryer for seaweed staring at $1,000. The conveyor belt dryer produces a continuous process, which is efficient [14]. After drying the seaweed, remove any rubbish material and cover the seaweed with salt crystals to preserve it up to 2 years for consumer use [15].

Densification

Densification of seaweed is a process that includes quite a bit of variation on the part of the companies buying and selling their product. Seaweed is an internationally prominent product that is gaining popularity in a variety of markets, and as such manufacturers are adjusting their processes to reflect these changing customer demands. Seaweed is harvested using a variety of cultivating methods and is usually dried before the farmer sells it to a processing company. During drying moisture content is reduced to approximately 25%-35% moisture content wet basis, removing water and allowing for lower shipping costs, increased efficiency on behalf of the buyers, and a higher quality material. Two common densification methods include baling, and pelleting.

Baling

Baling is the most common method of densification available to processing companies. Typically farmers will sell dried seaweed to local companies that densify the material in bales that can easily be loaded onto truck and boats to be shipped to customers [16]. Advantages of bales include that they are easily transferred and only require one machine--a baler--to produce. A disadvantage associated with baling is that because of the remaining moisture in the biomass, the potential remains for the seaweed to begin to spoil in the centers of the large bales.

Biomass is crushed into bales using a bailing press or seaweed baler that uses high pressures to densify the seaweed into a tightly-packed shape that is easily transferred. In the pacific islands, farmers ship loose, dried seaweed to companies where the biomass is compacted and shipped in the bags to their customers [16]. Spoilage of biomass in bales can be reduced by using mechanically drying the seaweed to a lower moisture content before forming the bales. While bales are one of the most widely used form of densification, current work is being done to improve the pelletizing of seaweed.

Pelleting

Pelleting, or densification, is a means to increase the bulk density of biomass materials, which will facilitate transportation, logistics, material handling, and storage operations. Seaweed can be used in pellets for animal feed principally as a binding agent but also as an additional source of protein and vitamins. Adding seaweed to feed at levels of 3% mass has been shown to noticeably improve the hardness of the pellet [17]. Seaweed is usually included at low levels in livestock diets (a maximum of 15% is currently approved in chickens), but can also be included at high levels as herbivore fish feed [18]. Producing seaweed pellets is most prominent in the aquaculture feeds and livestock feeds industries but is also used with organically grown livestock and promoted in low doses for every type of livestock by organic farmers [19]. In order to pelletize biomass, raw materials are first dried to between 12%-15% moisture content wet basis [20]. Additives and binding agents (occasionally seaweed) are added at this point and the biomass goes through an extrusion process where steam and heat are added before they’re formed into finished pellet shapes. Characteristics involved in the pelletizing process include initial moisture content, ratios of included components, and compression the biomass undergoes throughout the process. More research is necessary to determine the best conditions for seaweed pellet production.

The best method for densification of seaweed ultimately depends on how the biomass is used by the buyer. Currently seaweed is principally processed into agars, alginates, and carrageenans that are used in a variety of industries (Integrated Multi-Trophic Aquaculture, 2012). Production of agars includes soaking whole, cleaned seaweed in heated water to extract the jelly-like agar [21]. Alginates are usually developed through a process that uses seaweed flour to produce an important product used as a thickening agent in a variety of markets [22]. Carrageenans are also harvested from macroalgae by boiling raw seaweed [21]. Macroalgae can also be processed in converters that use heat and catalysts to break down the biomass into a mixture similar to crude oil that can be further refined to create biofuels [23]. Finally, when using macroalgae in livestock diets it is most easily used in pellet or ground meal form.

Addressing how biomass is to be used determines which densification method would be most appropriate for each supplier.

Transportation

Transportation is an important player in the harvesting and production process and greatly influences the efficiency of the overall system. Unfortunately, the amount of published scientific literature discussing seaweed harvesting is very minimal, and transportation practices are rarely mentioned within these sources.

Transportation between harvesting and processing

Philipsen [24] discussed some of the techniques currently used in the harvesting of brown sea weed. Two types of seaweed farms are in use today. In near shore farming, seaweed grows relatively close to shore, and a variety of successful planting systems are in use. An area being investigated farther is the development of off shore farming; this would allow larger farms and increased seaweed production, but involved more transportation. Harvesting practices off shore farming are limited due in part to the few number of off shore farms. While each of these two strategies are viable farming options, that transportation mechanisms used in each of the processes could differ dramatically. Philipsen shared that in a near shore farming operations a skiff, or small boat, transports seaweed from the harvesting rig to shore where it is processed (dried and densified), often times on skiff will make multiple trips from the harvesting unit to the shore [24]. In other situations the harvesting rig itself will transport seaweed from the location it is farmed to the shore. As farming moves farther offshore, produces would likely be deterred from using small skiffs, looking to transport more seaweed per trip to the processing facility. This would result in a move to larger barges or cargo ships in order to keep costs low, while minimizing the number of trips from shore to farm that are necessary.

Often times, a single drying/densifying operation is located near the coastline. Seaweed can be dropped off directly at the facility, or dropped off at the coast and transported via truck or train to its final destination. A facility with both drying and densification processes would be the most idea situation, but this may not always be feasible. Again, the dried seaweed could be transported vial truck to the location where densification occurs.

Transportation to final production site

Transportation out of the pre-processing phase is really where the scientific literature comes to an end. The transport of seaweed based biomass should be quite similar to other biomass materials. Sokhansanj discussed different techniques could be used for different densification practices. For round and square bales of corn stover (>1000lb per bale), several self-loading trailers are currently in use. After loading the bales onto these trailers, bales could be transported to the plant that finalizes processing. This equipment loads bales quickly, requiring only 10-20min, and will move up to 17 total bales [25].

Several sites also suggested that pelleting the material would also be possible; however no sites went in depth on transport of the pelleted biomass. Ideally, the pelleted material could be transported in a similar style as grains, using semi-trucks. The pellets could be transported bagged, or unbagged. These transport conditions would likely be determined by the final fate of the product [26-28].

While planting and tending to seaweed growth requirements is outside of the scope of this study these are also important to consider when evaluating the feasibility of either the near shore or off shore farming mechanism. After seaweed is planted divers are required to dive periodically to ensure that the seaweed is attaching as necessary. Transportation in each of these different situations could play a role in the overall efficiently of the system as a whole [29].

Conclusion

Seaweed harvesting holds great potential in the food, biofuel, and pharmaceutical arenas. With near limit less ocean area for crop production, many of the land shortage challenges of typical farming are mitigated. A successful operation, however, must fully consider the associated harvesting, drying, densification, and transportation operations presented in scientific literature, along with the type of waters they are planning to work in, be it offshore, close to shore, or a pond setting. The type of shore can greatly alter what type of machinery, boats, and transportation, which should be used. Clearly, much more work needs to be done to make this commercially viable on a widespread scale around the world.

To Know More About Open Access Journals Publishers Please Click on: Juniper Publishers

Comments

Post a Comment