Note on Critical issues with Boil-Off Gas Generating from Marine Fuel LNG- Juniper Publishers

Juniper Publishers- Journal of Oceanography and Fisheries

Note on Critical issues with Boil-Off Gas Generating from Marine Fuel LNG

Daejun Chang*

Department of Mechanical Engineering, Korea Advanced Institute of Science and Technology, Korea

Submission: February 17, 2017; Published: March 22, 2017

*Corresponding author: Daejun Chang, Graduate School of Ocean Systems Engineering, Department of Mechanical Engineering, Korea Advanced Institute of Science and Technology, Republic of Korea, Email: djchang@kaist.ac.kr

How to cite this article: Daejun C. Note on Critical issues with Boil-Off Gas Generating from Marine Fuel LNG. Ocean & fish Open Access J. 2017; 1(4): 555568. DOI: 10.19080/OFOAJ.2017.01.555568

Short Communication

The Marine Environment Protection Committee (MEPC) of the International Maritime Organization (IMO) decided at its 70th session in London in October 2016 that the 0.5% sulphur cap for marine fuels hall be globally implemented from 2020.This decision is in line with public opinion and global collaboration with respect to reducing the marine pollutants such as SOx, NOx, particulate matters, and even green-house gases emitted by ships [1,2]. Three options seem available for ship owners: low- sulphur fuel, scrubbers, and LNG (liquefied natural gas) fuel.

Of the alternatives, the LNG solution clearly shows the best environmental performance since this cryogenic fuel is free from sulphur and particulate matters with a significant potential for CO2 reduction [3]. Even in the event of fuel leakage, LNG just vaporizes into the atmosphere without significant impact on marine ecosystem. However, some challenges are identified for this solution regarding economics, safety, and environmental friendliness that are mainly related with the boil-off gas (BOG) from the cryogenic liquid fuel.

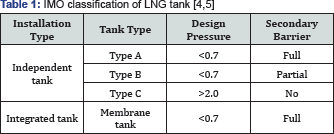

LNG is stored within a heavily insulated tank around-160 °C under the vapor pressure ranging from the atmospheric pressure up to 10 barg. Due to the large temperature difference from the surroundings, heat ingress into the tank, insulation, and connected piping leads to BOG generation. Unless the BOG is removed from the tank, the tank pressure increases gradually with time. So, there are two kinds of tanks in terms of operating pressure: pressure tanks and non-pressure tanks. The former hold the BOG within it at the expense of pressure rise while the latter emit BOG to keep the internal pressure near the atmospheric pressure. The IGC and IGF codes [4,5] further classify the LNG tanks depending on the installation type and need of secondary barrier against leakage from the tanks as shown in Table 1. Only Type C tanks are pressure vessels that can keep BOG inside and have no secondary barrier due to their invulnerability against leakage. The flammable gas BOG plays a critical role in judging safety and economics of ships carrying refrigerated fluids [6-9]. In order for non-pressure vessels of Type A, Type B, and membrane tanks to be used for LNG storage, BOG should be vented from the tanks and handled in appropriate ways such as re liquefying, burning, using as fuel, or exporting externally the BOG. Though all these approaches to BOG handling accompany dedicated equipment, trained crew, and additional expense, they make an economic sense for very large LNG carriers that are equipped with those non-pressure tanks [6,7]. To the contrary, the fuel LNG tanks for small ships have been of Type C tanks for the sake of no need of BOG handling.

This stereotypical choice of tank types is being questioned as large ships should be equipped with sizable fuel LNG tanks. Traditionally, Type C tanks are cylinders. So, to store a huge amount of fuel LNG without BOG venting means to install several cylinders inside the ship. This design concept makes no sense considering their drawbacks of wasting space between the multiple cylinders as well as increasing piping, instruments, and operational complexity. An alternative approach is to install such non-pressure tanks as for large LNG carriers. However, several critical issues should be examined carefully before taking this approach, especially from the view point of generated BOGs and their handling over the conceivable operational modes of the ship.

Figure 1 classifies BOGs in terms of two main operational modes and their origin. During the normal operation mode where the stored LNG is used as fuel, three kinds of BOGs can be generated: NBOGsteady, NBOGspray, and NBOGFlash. As the LNG bunkering consists of several steps [10], four additional BOGs should be considered for the bunkering operation. BBOGContained is the BOG inside the tank waiting for bunkering while the rest are related to cooling of the bunkering piping, the tank, and the insulation [11].

Due consideration should be paid to the following BOG- related issues when a big non-pressure tank is considered for fuel LNG storage for ships.

- The BOG generation rate during the normal operation can be greater than NBOGstead y due to the NBOGspray that is caused by the intermittent cooldown of the upper parts of the tank and insulation.

- Holding the BOG inside the tank for an extended period even below 0.2 barg can result in a huge amount of flashed BOG (NBOGFlash).

- Before the LNG bunkering, the BOG contained within the tank (BBOG contained) should be vented out of the tank and treated in an appropriate way. The current LNG bunkering infrastructure including bunkering ports and bunkering ships are not ready to receive the exported BOG from the ship. This means that the ship should be equipped with proper systems to reliquefy or burn the BOG.

- During the LNG bunkering, BOG can be generated due to the cool down of the bunkering piping, the tank, and the insulation. Since this BOG also cannot be returned to the bunkering facility, the ship should digest it in an appropriate way.

- The non-pressure tank cannot take LNG whose vapor pressure is greater than 0.2 barg while the current LNG bunkering infrastructure is usually supplying LNG at much higher pressure. So, the availability of the low-pressure LNG should be guaranteed.

Without addressing all these BOG issues, the use of nonpressure tanks for fuel LNG storage can hardly satisfy the performance goals of economics, safety, and environmental friendliness of ships, ports, and bunkering vessels.

Obviously, the best solution to fuel LNG storage in large scale would be a prismatic pressure vessel that could hold BOG and simultaneously fit into a limited installation space in a ship. The concept of the box-shape pressure vessel is not new in that ASME codes [12,] have already defined some rules for them. The challenge is how to scale up the prismatic tank without significantly increasing the tank weight. Recently, a new idea has been developed for the scalable prismatic vessel, called the lattice pressure vessel [14,15]. Unlike the conventional cylindrical pressure vessels, this tank employs an internal load bearing structure called the lattice structure. This technology may provide a solution to the fuel LNG storage for big ships satisfying both objectives of BOG holding and space efficiency.

To Know More About Oceanography & Fisheries Open Access Journal Please Click on: https://juniperpublishers.com/ofoaj/index.php

To Know More About Open Access Journals Publishers Please Click on: Juniper Publishers

Comments

Post a Comment